It was the deep, dark, snowy winter of 2015 when Lily Scott was introduced to the healing properties of bone broth. She and her husband and both of their kids were sick with colds, and her son, who was only three months old at the time, contracted a dangerous virus that made it difficult for him to breathe. She was already making homemade broth from all organic ingredients, and a friend encouraged her to fortify it with more bones and make real bone broth. She served it up to her family, and the results were immediate. Her son got better fast.

All winter long, Lily “broth-bombed” her friends and family, who soon began to ask how they could pay her for her product. She bought a freezer for her garage, stocked it with frozen broth, and filled orders from the driveway. Once she outgrew her home kitchen, she negotiated with a chef friend to share kitchen space in his restaurant. By fall 2016 she was making bigger batches and began to sell her bone broth at farmer’s markets and through specialty retailers such as Back to Basics in East Greenwich.

“Rhode Island has wonderful farmers who raise meat and vegetables the right way. I can use everything that’s in our backyard and support our local commerce.”

“My husband and I talk a lot about what’s the idea, what’s the thing that we love, what we can be passionate about,” says Lily. “What we can put out into the world and know that it is good and valuable, and feel happy that we are adding a brick into the fabric of our now for the future. I came home one night from teaching a yoga class and said to him, It’s broth!”

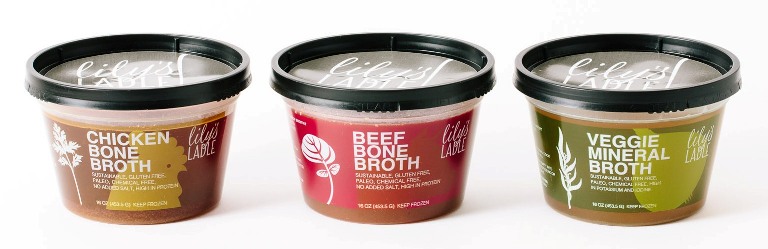

Lily’s Ladle was born. There are three flavors: chicken bone broth, beef bone broth, and vegetable mineral broth. All the ingredients are sourced locally from farms that follow organic, environmentally sustainable practices.

“We are authentic slow-cooked bone broth still done the way that you want it done, from homemade,” says Lily. “It is a salt-free, chemical-free product that you can use the same way that you would a broth you buy in a box or a can, but it has no chemical components, it has much more nutrient density, and it’s going to make your food taste better.”

As Lily was learning her way around a commercial kitchen and earning all her food industry certifications, the market for bone broth was taking off. She was doing all the cooking, all the packaging, and all the distributing for her products. A friend had introduced her to Social Enterprise Greenhouse and recommended the Food Accelerator program, but she wasn’t quite convinced.

“I was thinking, I don’t really have a company, I just have this little thing that I’m kind of maybe doing,” she explains. “Then I had three weeks where I just could not get out of my own way. I would do something and I would mess it up. I burned a batch at the kitchen and had to throw it all away. I made a big batch, but the freezer was full, and I hadn’t thought to check ahead. I just kept messing up.” Lily called SEG and asked if she could be considered for the 2017 Food Accelerator, even though it was past the initial deadline to apply.

“Isabella, who was head of the program at the time, told me to come in,” she continues. “I explained what I was doing and she said, ‘You’ve got your recipes, you’ve got your concept, you’ve proven that it’s a workable viable product because you’re testing it in these small grocery stores and at the farmer’s market, and you’re in the now-what phase.’ I was like, yeah, exactly.”

The SEG Network Effect

Before moving to Rhode Island, Lily had worked for eight years in the hospitality industry in New York City. She had loved her work community and wanted to create a similar vibe for herself here. She hoped that being a maker of delicious bone broth would lead her toward it.

“Just food and water and time and love.”

“When I had my ‘It’s broth!’ moment,” she says, “I realized, this is how I can make something here in this place. Rhode Island has wonderful farmers who raise meat and vegetables the right way. I can use everything that’s in our backyard and support our local commerce, and I don’t have to make a bazillion dollars, but I can make this product and grow this brand. And people in Rhode Island love to eat, and they love to support their local food.”

For Lily, who already had a master’s degree in teaching, SEG’s Food Accelerator was a second master’s program, this time in food entrepreneurship. The most significant lesson came late in the program during the marketing segment. “Jo from United Natural Foods brought in a whole host of experts and her team and they worked with us one on one,” she says. “She walked us through this branding exercise of breaking down our products and using our value proposition and all of our market research and our ratios and our budgets and everything that we had learned so far. It all seemed like way too much, but she showed us what to do with it.”

By the end of the exercise, Lily knew how to define her customers’ needs and address them with the right marketing messages. She also learned the importance of collaboration. “I’m kind of a one-woman show, and sometimes it can feel like I’m just yelling by myself in a room,” she says. “Jo reminded me that I wasn’t alone and that I was more likely to fail if I didn’t use the people who were there with me in the room. Not only did she give us all our branding guidelines, she also reinforced the fact that we should utilize each other.”

Since graduating from SEG’s Food Accelerator, Lily’s Ladle has hired three employees, increased production by 300 percent, and built out its distribution channels. Lily is now sharing a nearby commercial kitchen facility with Lost Arts Cultured Foods, which was a fellow participant in the same SEG Accelerator program. She sources her chicken bones from Baffoni’s Poultry Farm and a few other places. She gets her beef bones from New England Grass Fed Beef at Cloverbud Farm in Portsmouth. The online service What’s Good has also provided connections to reliable sourcing from sustainable producers.

She’s moved far beyond those early days of renting a booth at a farmer’s market and selling pints of bone broth by hand. “Every week I make three batches, each of my flavors,” she says. “That makes about 140 pints, or about 23 cases. Every 10 days we fill up a mixed pallet and send it off to a frozen foods warehouse, and they deliver my product to the distribution centers and a couple of independent online marketplaces that I work with.”

Lily stays in touch with her SEG Food Accelerator advisor, Betsy Santarlasci, who continues to be an invaluable resource. She also relies on SEG advisor Tony Fonseca from Packaging and More for regular guidance. Lily’s Ladle bone broth is now available at numerous fine grocers throughout New England and New York, and it was just picked up by 70 Big Y supermarkets in Massachusetts and Connecticut. In June 2019, Lily’s Ladle won a pitch slam contest hosted at the UNFI Trade Show at Mohegan Sun, beating out nine other emerging brands. A couple of new products are in the works.

What’s the secret recipe for all this success? “Just food and water and time and love,” Lily says with a smile.